Welding manipulator is generally composed of column, boom, rotary mechanism, trolley and other parts.

Application of welding manipulator: The welding manipulator is a special welding and positioning equipment combined with welding rotator and welding positioner to automatically weld the inner and outer circumferential seams, fillet welds and inner and outer longitudinal seams of tank , pipe , vessel, shell. It has various structural forms such as fixed, rotary and all position. According to the needs of users, the structure can be selected and various welding machines can be equipped. Weld-fab can also equip flux recovery machine, Submerged arc welding system, MIG welding system, Monitoring System , Welding seam tracking and Welding oscillator .

Composition principle of welding operator: it is mainly composed of operation device, control device, power source device and process guarantee device.

1) The operating device includes guide rail, angle adjusting mechanism, vertical guiding mechanism, welding gun clamp and welding gun. The angle adjusting mechanism can make the welding gun rotate positive and negative around the center.

2) The control device is composed of electrical control system, which can control the working state of welding operator.

3) The power source device is composed of air cylinder and is driven by air pressure for power transmission.

4) The process guarantee device is composed of wire guide mechanism, wire guide pipe and wire guide nozzle, which can realize the automatic orientation of welding wire and ensure the welding quality.

The welding manipulator can cooperate with the special welding parts displacement mechanism to realize the clamping of the cylinder body at one time, and two welding guns can weld the left and right sides at the same time, which greatly improves the machining accuracy and production efficiency

Welding manipulator is generally composed of column, Boom, rotary mechanism, trolley and other parts. Each component is a building block structure, and the general column and beam are its basic components. The rest parts can be selected according to the user’s requirements. The column and beam adopt bending welding structural parts, which have good rigidity. All of them are heavy-duty and light-duty planing machines with square guide rails. The high precision and wear resistance of the guide rail are ensured. It is used for longitudinal and circumferential seam welding of inner and outer seams of cylindrical workpieces such as boiler drum and petrochemical vessel in pressure vessel.

Unique cross-section design of beam and column, stress relief after welding, planing and grinding. Light weight, high strength and good stability. The design of the telescopic arm in the beam can effectively increase the horizontal expansion distance of the beam.

The boom lifting adopts constant speed mode of AC motor, which is stable and uniform with high safety factor. With safety device.

The beam retraction, column electric rotation and electric trolley adopt AC motor frequency conversion stepless speed regulation, constant torque output, stable speed (especially at low speed), fast start or stop, speed digital display and preset.

The column rotation is divided into manual and electric. The slewing bearing adopts the products of domestic famous brand manufacturers, with high-precision gear, which can rotate flexibly and can be locked manually, which is safe and reliable.

The trolley adopts standard railway track as walking track, which is divided into manual and electric. Manual is suitable for light and small moving range operators, while electric ones are suitable for heavy or large moving range operators.

Manual control box and head control box (welding control box) are adopted to form near control and remote control mode. The operation is flexible and convenient. Linkage interface is reserved in the electric box, which can realize synchronous linkage with roller carrier, positioner and circular rotary table.

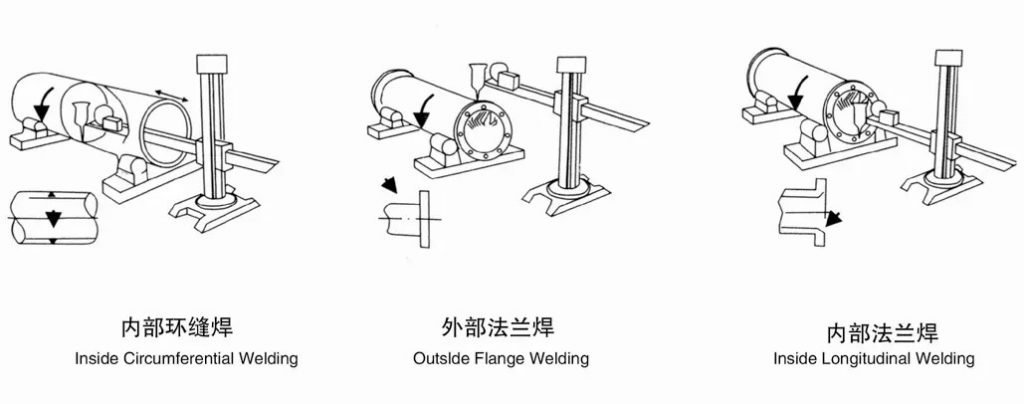

Welding manipulator can use with Welding Rotator for automatic welding , for tank inside and outside long seam, for tank inside and outside circular seam. See the sktech below.

Welding manipulator can be also link with Welding positioner for elbow pipe welding , flange welding, etc. See the sketch below.

Using Welding and Positioning Equipment, such as Welding Manipulator , Welding Rotator and Welding Posiotioner, Welding turntable, not only can improve the welding quality , but also can reduce the welder work efficiency.

To get more information , please visit www.weld-fab.com or send inquiry to info@weld-fab.com , let our experienced sales engineer give your effective suggestions.