CHOOSE US BE YOUR SPECIALIST SUPPLIER !

Development, design, manufacturing, installation, maintenance and personalized training system.

PRECISION MANUFACTURING

WE HAVE A COMPLETE SET OF RESEARCH, DEVELOPMENT, DESIGN, MANUFACTURING, INSTALLATION, MAINTENANCE AND PERSONNEL TRAINING SYSTEM.

QUALITY CONTROL

WE HAVE OUR QC PRACTICES AND PROCEDURES WHICH EMBODIED IN THE STRICT PRODUCT QUALITY CONTROL MANAGEMENT

GLOBAL WARRANTY

WE HAVE OUR WORLDWIDE SERVICE TEAM, INCLUDING INSTALLATION, DEBUGGING,ACCESSORIES PROVIDING AND TECHNOLOGY SUPPORTING.

WORLDWIDE PROJECTS!

Welding and Positioning Equipment Using Knowledge

What is the Welding Rotator ?

The welding rotator is kind of an automatic tool for making it much easier to weld pipes, tanks, piles and other rounded objects. They can handle small or even large sizes and save time by creating two moving pieces of metal to join together, leaving both hands free to do welding.

They can loading light and heavy duty workpiece by hand remote.

What is the Welding Positioner ?

Welding positioner a variety of mechanical devices that change the position of weldment or welder to complete mechanized and automatic welding.

Welding positioner can be divided into three categories

(1)Welding parts displacement machinery: including welding positioner, welding rotators, welding turntable and welding turnover machine.

(2)Welding machine positioner: including welding operator and electroslag welding stand.

(3)Welder positioner: including welder lift, etc.

The welding positioner is a kind of machine which can rotate and tilt the workpiece, so that the weld on the workpiece is placed in a favorable position for welding. It is mainly used for turning and tilting weld frame, flange and head, and can also be used for assembly, cutting and inspection.

Welding turntable is a kind of simplified positioner. It rotates the workpiece around the vertical axis or at a fixed angle. It is mainly used for welding, surfacing and cutting of rotary workpiece.

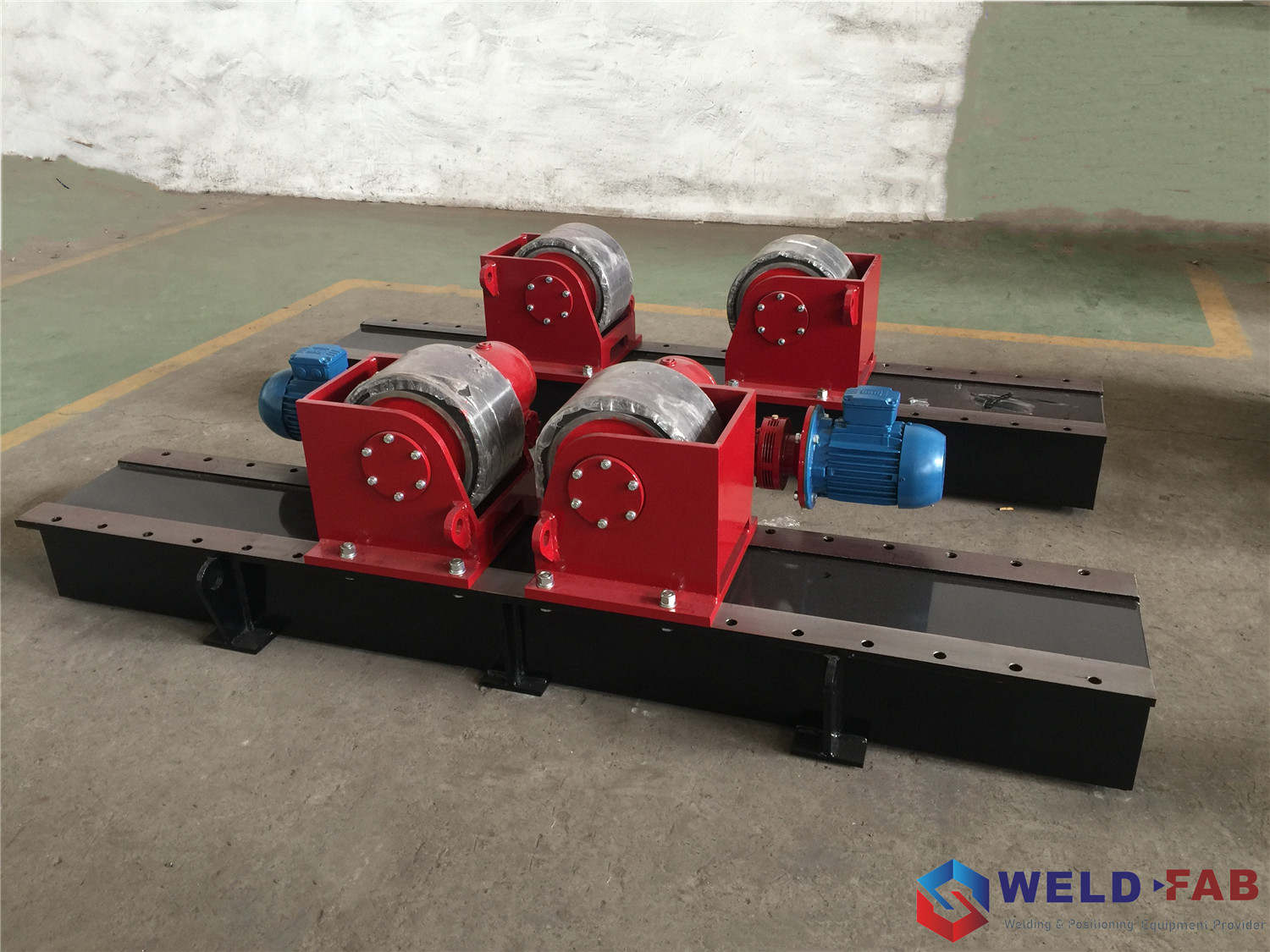

How to choose the Welding Rotator ? The Conventional Welding Rotators or the Self-aligning Welding Rotators ?

Self-aligning Welding Rotator : The Self-aligning Welding Rotator is composed of two groups, include the drive roller and the idler roller. Each group of the active and passive frames of the self-aligning welding rotator series consists of four rollers. The rollers are made of inner iron core and outer polyurethane. The operation of the driving roller is driven synchronously by the speed regulating motor through two worm gear reducers, and the speed controller is used to realize no speed change. The mechanical transmission noise is low, and the workpiece rotation is stable. The linear speed of the workpiece rotation is 100-1000mm/min. Each group of clamp supports can automatically adjust within the range of the workpiece diameter. When the diameter is small, the lower wheels of each clamp frame are on the same horizontal line.

Conventional Welding Rotator: Conventional Welding Rotator is also equip with one drive roller and one idler ,and the control cabinet with hand remote. Each unit only have two rollers, and the roller is inner metal, outside coated with polyurethane which drives the pipe to rotate with the help of friction between active roller and pipe. The driving device adopts frequency conversion speed regulating motor, and drives the welding parts to do welding rotation through the reducer. The spacing adjustment of roller parts in each roller carrier is completed by manual operation and positioning bolt according to the condition of weldment.

Design of welding fixture for welding and positioning equipment

- The welding fixture should be fast and easy to operate, and the operation position should be in the position which is easy for workers to access and most suitable for operation. In particular, the operation force of the manual fixture should not be too large and the operation frequency should not be too high. The operation height should be set at the position where the worker is most likely to exert force. When the fixture is in the clamping state, it should be able to self-locking.

- Welding fixture shall have enough assembly and welding space, which shall not affect welding operation and welder's observation, and shall not hinder the loading and unloading of weldments. All positioning elements and clamping mechanisms shall be kept at a proper distance from the weld bead or arranged under or on the side of the weldment. The actuator of the clamping mechanism shall be able to retract or transpose.

- Reliable clamping and proper rigidity. When clamping, the location and geometry of the weldment are not damaged. After clamping, the weldment will not be loose and slip, and the constraint of the weldment will not be too large to produce large stress.

- In order to ensure the safety of use, necessary safety interlock protection devices shall be set.

- During clamping, the surface quality of the weldment shall not be damaged. When clamping thin pieces and Weldments of soft materials, the clamping force shall be limited, or measures such as limiting the stroke of the indenter, increasing the contact of the indenter and adding copper and aluminum backing shall be taken.

- The heat insulation of the handle and the damage of welding spatter on the surface of clamping mechanism and positioner shall be considered for the fixture close to the welding part.

- The force application point of the fixture shall be located at the support of the weldment or near the support to prevent the formation of couple between the supporting reaction and clamping force, between the support reaction force and the gravity.

- Pay attention to the special requirements of various welding methods on the fixture in terms of heat conduction, conduction, magnetic separation and insulation. For example, in projection welding and flash welding, the fixture is also used as a conductor; in brazing, the fixture is also used as a heat sink, so the fixture itself is required to have good conductivity and thermal conductivity. Another example is the fixture used in vacuum electron beam welding. In order not to affect the electron beam focusing, the fixture parts near the gun head shall not be made of magnetic materials, and the fixture shall not have residual magnetism.

- The fixture used for large-scale plate welding structure should have enough strength and rigidity, especially the specific stiffness of clamp, which has great influence on the shape accuracy and dimensional accuracy of the structure, and large redundancy should be reserved in the design.

- In addition, it is not suitable to use only one type of power source and clamping device in the same structure.

- The fixture itself should have good manufacturing technology and high mechanical efficiency.

- The universal and standardized clamping mechanism and standard parts shall be selected as far as possible to make welding fixture.

Welding Rotator Projects

Welding Rotator Projects Welding Positioner Projects

Welding Positioner Projects