Pipe Rotator

Weld-fab is one of the best companies that makes pipe rotators for welding. They have been making these pipe rotators for more than 15 years. If you need a pipe rotator, Weldfab can be trusted to make a great product.

Weld-fab makes a lot of different types of welding positioners. You can use them for all sorts of projects, no matter how big or complex they are.

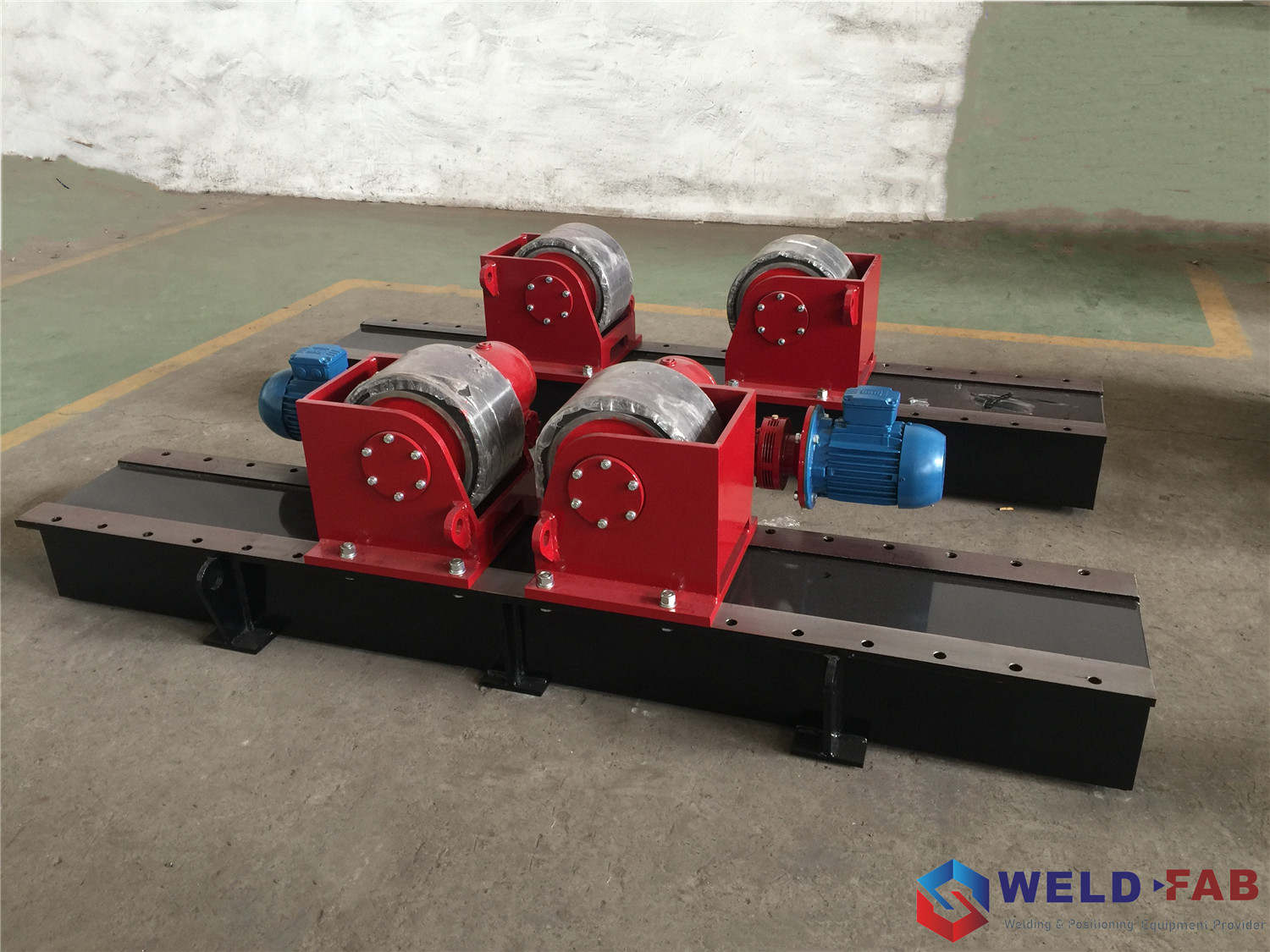

Weld-Fab Welding Rotators

Self-aligning Welding Rotator

Conventional Welding Rotator

Weld-Fab Welding Rotator Video

Why Choose Weld-Fab Rotators?

√ Standard match with CSA & CUL and CE

√ Stable mechanical structure

√ Safety electrical design

√ Special customized loading capacity and dimension

√ Superior warranty and after service

Frequently Asked Questions About Pipe Rotator

Pipe rotators are one of the best ways to pipe fluids through a pipe. They can rotate full or partial pipe sections and they can be used in many different pipe sizes. Pipe rotators are designed for high pressure, medium pressure, low-pressure fluid lines, and vacuum lines. With so many different types of pipe rotators on the market today, it’s hard to know which one is right for your application. Let’s answer some frequently asked questions about pipe rotator selection:

What is Pipe Rotator?

Pipe Rotators are helpful tools that can be used to help you with your welding projects. They’re typically allow for more control over the position of pipes or other cylindrical parts during production runs in manufacturing plants all around world!

Where pipe rotator can be used?

There are many types of pipes that can be used in pipe rotators. Some common ones include:

Long Radius Bend Pipes, Elbow Pipes and TeePipe Flanges Wye-Style Partitions And Many More!

What are benefits of pipe rotator?

Pipe rotator can give you these advantages and benefits!

First, it’s safer for your welder because they’ll never have to worry about aligning their welds. Second, with pipe rotators all set up properly the workpiece stays put so there is no more need of chasing around trying find where things went flying off at once during production runs when everything has been laid out beforehand using this method instead . Finally whistle workers only get charged fractionally higher rates than normal due tp its efficiency compared wth other methods used today.

What size of pipe rotator should I use?

The pipe rotator you choose will depend on the pipe size you are using. There are pipe rotators available for all common pipe sizes. Contact us for more details of pipe rotator

How do pipe rotators work?

Pipe rotator rotate the pipe section in either a clockwise or counterclockwise direction, allowing you to pipe fluids through your line without any issues! Pipe rotators are available for all common pipe sizes and they can handle high pressure, medium pressure and low-pressure fluid lines!

What is a pipe rotator’s range of motion?

Pipe rotators have a range of motion that will depend on the model you choose. Some pipe rotators can rotate the entire pipe section, while others can only rotate part of the pipe section.

How To Select the Best Pipe Rotator for Your Welding Operations?

1. Consider the vessel’s scale and strength when selecting a welding rotator for your operations.

2. Assess the device’s durability and loading capability to ensure that it is appropriate for your workpiece.

3. Try welding rotators that are qualified and accredited in your field, such as those that are certified by the industry.

Either way, you should check out the Weld fab website for more information on welding rotators!

Can pipe rotators be used for hazardous materials handling?

Yes, pipe rotators can be used with a variety of different pipe sizes and pipe material. They are designed to handle high pressure, medium pressure, low-pressure fluid lines, and vacuum lines. Pipe rotators rotate the pipe section in either a clockwise or counterclockwise direction. This makes it easy to pipe fluids through pipe lines. Pipe rotators are available for all common pipe sizes and can be used with most pipe materials.

Will pipe rotators be able to handle the pressures in my line?

Pipe rotators are designed for high pressure, medium pressure, low-pressure fluid lines, and vacuum lines. They can handle the pressures in your line without any problems. Pipe rotators rotate the pipe section in either a clockwise or counterclockwise direction. This makes it easy to pipe fluids through pipe lines. Pipe rotators are available for all common pipe sizes and can be used with most pipe materials.

Why Choose Weld fab For Your Pipe Rotators?

You can bet on us to deliver the best results. We have been deemed as efficient and effective by our clients, who experienced a surge in sales because of it!