WELDING TURNTABLE

WELD-FAB supply all kinds of welding turntables. To learn more about welding turntables, please contact with our sales team.

* Loading capacity from 600kgs to 100,000kgs

* Power supply customized from 110V to 600V

* Customized table diameter and center height

* Adjustable rotation speed

*Control mode can choose VFD or PLC

Weld-Fab Welding Turntable

Weld-Fab Welding Turntable Video

Why Choose Weld-Fab Turntables?

√ Standard match with CSA & CUL and CE

√ Stable mechanical structure

√ Safety electrical design

√ Special customized loading capacity and dimension

√ Superior warranty and after service

Welding Turntable – The Complete FAQ Guide

A lot of people get confused in understanding what a welding turntable is. That is the very reason why we’ve created this guide!

Upon the end of this FAQ guide about welding turntables, you’ll have every idea of what welding turntables are! Furthermore, we will also help you by guiding you to work with the best welding turntable manufacturer and supplier!

So, without further ado, let’s jump right onto the guide!

What is a Welding Turntable?

A welding turntable, also known to be welding rotating tables, are machines and equipment that offer complete assistance to welding processes and procedures.

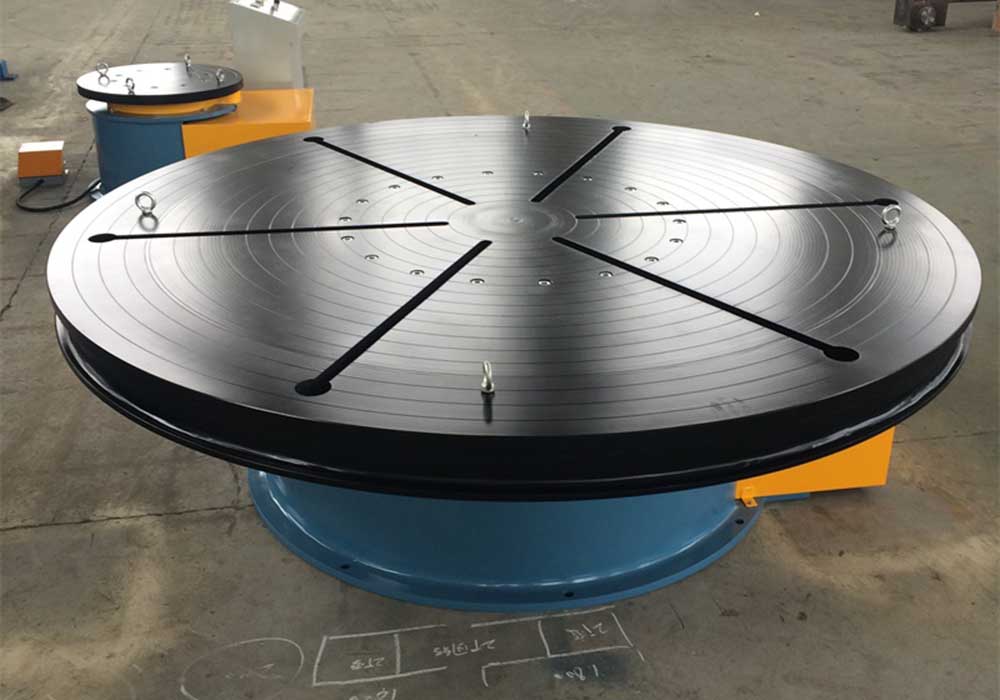

Image of what a welding turntable looks like

Many people get confused in distinguishing welding turntables from welding manipulators. To cut it all short, they’re not the same – we’ll have a more detailed discussion about that in the latter part of this guide.

Is a Welding Turntable the Same as a Welding Positioner?

No, welding turntables are different from a welding positioner.

Sample image of a welding positioner

Yes, they both carry the same purpose, but they’re not a single machine. Let’s look at the main differences of these two.

Welding turntables are the machines you’ll usually use if you want the workpiece to be automatically rotated, twisted, and turned. The locomotion that it offers is just singular – it just rotates in its horizontal axis.

Welding positioners, on the other hand, are machines and equipment that you want to use if you want to maneuver your workpiece in a 360-degree axis, both vertically and horizontally.

Those are the distinctions between welding turntables and welding positioners.

How Do You Use a Welding Turntable?

Welding turntables, akin to other auxiliary welding equipment, are fairly easy and simple to operate.

As a matter of fact, here’s a detailed step-by-step procedure on how you can use and operate welding turntables.

- The first thing you need to do is to try and setup the welding turntable. Plug in all wires and cables appropriately.

- Before starting it up, check if all the cables and wires are going into the correct power (voltage, watts, etc.).

- Once you have everything in place, try to power and start up the welding turntable. Don’t place the workpiece on it first, what you have to accomplish in this step is to test out if your welding turntable is functioning properly.

- Check all the gears, setting, the control panels and systems, etc.

- Also, you want to check if it’s capable of rotating or spinning in the speed that it states based on its specifications.

- Check all other functionalities without any workpieces first.

- Once you’re sure that everything is in place, what you want to do next is to try out welding a workpiece using the turntable. Don’t load it with heavy materials and complicated stuff first, try out easy and lightweight ones.

- After those have been finalized, the next thing you want to do is to test out the real-size workpieces you’ll work on.

- Try it out slowly before bombarding it with heavy items and workpieces, don’t force it all of a sudden.

That’s just about how you use and operate welding turntables! Hopefully, you were able to understand it!

What Are the Parts of a Welding Turntable?

Various welding turntable manufacturing companies and suppliers produce different types and variants of it.

An image that clearly showcases the differnet parts of a welding turntable

Some have added parts and components, while others substitute it for another one.

Nevertheless, here are the general parts and components of welding turntables.

NOTE: These are the parts that are mandatory. You wouldn’t be able to operate and use a welding turntable if you don’t have these.

Electricity and/or Power System

This is one, if not the most important part of a welding turntable. Without it, you wouldn’t be able to activate or turn the machine on.

Older versions of welding turntables, especially those that are manual, wouldn’t have power or electricity systems installed, though, so take note of that.

Spindle or Turntable

The spindle or the turntable is the part that’s responsible for the easier workload you’ll handle. It’s the place where you put and place the workpiece so that it could be rotated and turned.

Base or Support

The base or the support, from what it’s called, is the part of the welding turntable that supports the entirety of the machine.

It’s impossible for a welding turntable not to have a base – what would support it?

Rotational Gears

Lastly, these gears are the components responsible for the twisting, spinning, and the rotating of the workpiece.

If a welding turntable misses these gears out, it wouldn’t be considered as a welding turntable. Instead, it’ll just be known as a regular welding table.

These are among the most important and the most relevant parts of welding turntables. Again, the parts on this list aren’t everything, but, they are the most common and the most general to the extent that not having them would make a welding turntable just a regular welding desk or table.

Can You Make a DIY Welding Turntable?

Yes, a lot of home engineers and innovators try to create their personal versions of weld turntables.

Sample image of a homemade welding turntable (drill-powered)

As a matter of fact, there are numerous YouTube videos that are about it!

To help you with it further, we tried compiling the best manufacturing procedures and processes in creating welding turntables, they are:

Step 1: Sourcing of Items and Materials

Like how all production and creation processes start, the materials for creating homemade welding turntable are sourced first.

This would include:

- The metals,

- Gears,

- Pipes,

- Power or the electrical system

Step 2: Creation of the Base

As we can recall from the previous part of the guide, the base is relevant. Without it, you wouldn’t be able to call your machine or your equipment a welding turntable.

From all the materials you sourced, you need to form and shape the sides.

This would include the main walls of the machine, which will be four (4), the base (1), and the top part (1). All in all, 6 exactly shaped metallic sides.

Weld them together and you get the base of your welding turntable.

NOTE: The base needs to be sturdy because it’ll be the one to receive all the weight from the turntable itself – to the weight of the workpiece.

Step 3: Styling and Designing of the Turntable

Once your base is all set up, the next thing you want to do is to style and design your turntable.

You can have the faceplate or the main rotary table to be flat without any holes. On the flipside, you can also design it so it could have holes that would be used as inlets for chucks and jigs.

This is also the step in the process where you need to consider the overall functionality of your welding turntable because the style and the concreteness will dictate how the machine or the equipment would work.

Step 4: Shaping and Forming of the Main Body

Once that’s all done, the next thing you have to do is to form the main body of the welding turntable by attaching the gears, the faceplate or the turntable, as well as the base.

They should all be synchronized with each other to avoid failures.

Step 5: Assembly of Pieces

Finally, assemble all the pieces. More often than not, the power system or the electrical control system is the last part to be added to the masterpiece.

This is because it’s the easiest one there is.

Step 6: Test It Out First

Just like what we said above, don’t use and bombard it with heavyweight workpieces and items. Start out by playing with it first; rotate and spin it without any workpiece, and start to add small and light ones.

After you deem that you’re successful in creating a homemade welding turntable, start using it like how you would use a regular welding turntable.

What is the Purpose of Using a Welding Positioner?

Unlike welding turntables, welding positioners offer quite a few other uses rather than just positioning the workpiece.

While the main purpose of it is to assist welders with their welding procedures, you can also use rotary welding positioners for other stuff, too, such as:

- You can use it to keep all parts and other elements in place during welding

- You’ll be able to use it for the positioning or the maneuvering of a workpiece

- You can use it to make any large assembly process easier (depending on the size of the weld turntable)

- You can use it to assist in the mounting of your welding equipment

These are just some of the most common and the most sought-after uses of welding positioners. You can find a lot more of them when you try and use it for yourself!

What is a Welding Positioner Kit?

A welding positioner kit is a type of package that you order so you can create your own.

An example of a DIY welding positioner kit from Certiflat

Unlike sourcing out for materials, welding positioner or welding turntable kits will already give you what you need!

NOTE: Some manufacturers might not include the power or the electrical source, so you have to find one yourself.

Can You Use Welding Turntables For Automatic Welding?

Yes, as a matter of fact, welding turntables are used in complement to other welding machines and equipment.

A welding turntable with a column & boom welder

For instance, a column & boom welding manipulator can work hand-in-hand with a welding turntable to fully remove the need for a welder.

Another common scenario is that static weld heads are used with welding turntables so that the weld remains as is without any inaccuracies and non-precise welds.

Pros and Cons of Using Welding Turntables

While it’s easy to see all of the benefits and the advantages of using welding turntables, it’s not all rainbows and butterflies.

To tell you more about them, here are the advantages and disadvantages of using welding turntables.

Pros of Using Welding Turntables

Here are some of the pros or the advantages of using welding turntables.

Less Fatigue For Welders

One of the primary benefits of using welding turntables is that it gives less fatigue to welders. Since the workpiece will be rotating and spinning on its own, the welder does not have to move frequently.

It Increases the Safety of the Welder

Following the first benefit, welding turning tables also improve and increase the safety and the security of the welder.

Imagine welding a 10-ton workpiece – doesn’t that sound too dangerous for your welder? When you decide to use a welding turntable, the safety and the security of the welder is heightened.

It Improves Weld Accuracy and Precision

Another benefit of using welding turntables is the fact that it can fully improve and develop the precision and the overall accuracy of the weld.

Since its movement will be based off of the program to the welding turntable, you can be sure that it won’t fall out of alignment.

It Can Save a Lot of Time

Last but definitely not least is the fact that using welding turntables can save you time.

You can expect your work to be faster and to be much more urgent compared to welding it manually.

Those are the actual things welders look for, that’s why they use welding positioners; but, what about its cons and drawbacks?

Cons of Using Welding Turntables

Some of the unwanted and the disliked factors about welding turntables include:

It’s Costly and Pricey

Let me be straightforward and direct – welding turntables are costly and expensive. As a matter of fact, they’re not just worth a few hundred dollars.

Welding power supplies usually cost around $3,000 to $5,000. If we put it altogether, welding turntables can cost between $18,000 and $100,000 – there are some that even cost $250,000+ for advanced features and mechanisms.

It Requires Preventive Maintenance Programs

You don’t want your welding turntables to be broken or bricked all of a sudden, right? And in order for you to avoid this kind of problem, what you have to do is to write up and establish a maintenance program for it.

Maintenance programs are things that operators and welders need to follow for the proper use of the machine or the equipment.

Without one, the machine could be used wrongly and incorrectly.

The Welder Wouldn’t Be Flexible Enough

Last but most definitely not least is the fact that it has issues with flexibility.

With welding turntables, the only movement it has is on its horizontal axis. Comparing them to regular welding positioners, which can tilt, twist, and turn workpieces, they have less of a functionality.

As you may have noticed, most of these cons are easily controllable and manageable. All of them have workarounds and are easy to address.

Nevertheless, it’s imperative for you to know and to find all of these out so you know what to expect.

These are the pros and cons of using welding turntables, whatever industry you might be in.

Where Can You Find Welding Turntables For Sale?

You’ll be able to find a lot of welding turntables for sale in the market. Whether you want it brand new or secondhand, there’ll never be a shortage of it!

There are a ton of welding turntable suppliers and manufacturers in the world. In addition to that, you can also spend time searching for these machines and equipment in retail outlet stores.

You’d have to consider a couple of price differences though when it comes to purchasing them in bulk or in wholesale and purchasing them in retail.

But, the simple and the easy answer to this is yes, you’ll be able to find welding turntables in the market.

What is a Welding Floor Turntable?

Welding floor turntables are turntables that you’ll only be able to see lying and being installed on the floor.

An image of what a welding floor turntable looks like

The only difference it has with welding turntables is with how it’s used and where it’s placed.

What Processes Can You Do With Welding Turntables?

Welding turntables, just like how welding positioners and other welding auxiliary equipment function, you can perform a ton of welding processes and procedures if you use welding turntables, these procedures and processes include, but are not limited to:

- Metal Inert Gas (MIG) Welding or GMAW

- Tungsten Inert Gas (TIG) Welding or GTAW

- Submerged Arc Welding (SAW)

- Flux Cored Arc Welding (FCAW)

- Shielded Metal Arc Welding or SMAW

These are the most common welding processes and methods used. And, to put emphasis on the fact that they’re not everything, your choices for welding aren’t just limited to them.

What’s the Usual Weight Capacity of Welding Turntables?

There’s not a median weight when it comes to the weight capacities of welding turntables.

You can purchase and have a myriad of types and kinds of welding turntables in the market. Therefore, you can also expect that its sizes and weight capacities are different.

If you’re talking about the welding floor turntables, though, the capacities that it can support would be more than 500 pounds or about 226 kilograms, up to 100,000 pounds or 9,070 kilograms.

What Add-Ons and Accessories Can You Purchase With Welding Turntables?

You can purchase many different types and kinds of add-ons with your welding turntables, if you decide on it.

A welding chuck and/or jig – one of the add-ons and accessories you can purchase

These accessories and add-ons are extra items and materials that can further the assistance that your welding turntables give you.

To name few and the most common add-ons, they include:

Work Holding Materials

These are the items or the materials that you can purchase with your turntables for added grip or support for the workpiece.

Some of the most common work holding materials include chucks, grippers, fixtures, jigs, and others.

Pendants

Aside from holding and gripping materials, you can also purchase added things such as pendants, foot switches, or any other type of material that can serve as the setting or the toggling of the welding turntable’s speed, rotation, etc.

Torches

Since the primary function of welding turntables is to rotate and spin the workpiece on its horizontal axis, you still need to hold the weld head.

If you don’t want to be involved in such a tedious job, you can purchase additional stationary and standing welding torches, these are torches that just stand in one (1) position. Therefore, you don’t need to stand and hold the welding gun.

What Specifications Should You Look For in a Welding Turntable?

Before you decide purchasing welding turntable A, you need to make sure that you know the specifications of it first.

Just like purchasing smartphones and other gadgets, the specifications that you need to see are:

- Load Capacity

- Footprint or the Dimensions of the Overall Welding Turntable

- Eccentricity

- Power or Energy Requirements

- Rotational Speed

- Mass of the Equipment

- Table Span or Table Size

Apart from these specifications, it’s also imperative that you know about other accessories and add-ons you can purchase, too.

This can help you decide which welding turntable to choose.

Where Can You Purchase High Quality Welding Turntables?

You have a lot of different options in choosing a welding turntable. As a matter of fact, there will never be a shortage of it in the market.

The dilemma that most businesses face is in choosing which manufacturer to trust.

Since a lot of businesses today look like they’re doing the same things as others, it’s becoming more and more difficult to see the pros and cons of choosing a supplier.

Here with us at Weld Fab, we never take our clients for granted. As a matter of fact, we relay all of the information and the relevant data we have to them so that they’re knowledgeable about it.

For instance, they can purchase custom welding turntables that are specific to their business. They can send us designs and specifications they want to see!

Features of Weld Fab’s Welding Turntables

Our welding turning tables are so popular that even American companies patronize our products.

Some of the most notable features of Weld Fab’s welding turntables include:

- You can separate and divide it through several functions:

- Rotary Welding Operator

- Fixed Welding Operator

- Mobile Welding Operator

- We’re open to doing factory and manufacturing plant tours, both physically and virtually

- We can show you test results that we perform before we deliver it to you

- All of Weld Fab’s technicians are easily contactable in the event that you have questions and concerns

Reach out to us today and get a free quotation of your orders! With Weld Fab, your nightmares of not getting the right welding turntables will come to an end!