WELDING Head Manipulator

WELD-FAB supply all kinds of welding positioners, includes head tail stock welding positioner, L-type welding positioner, hydraulic welding positioner, manual elevating welding positioner, fixed welding positioner and etc. To learn more about welding positioners, please contact with our sales team.

* Customized lifting stroke and telescopic stroke

* Optional components : Welding system, Flux recovery system, Seam tracking/oscillating system, TV monitoring system

* Different welding solution, Submerged arc welding, Gas shielded welding, Argon arc welding

*Suitable for all kinds of inner and outer circumferential and longitudinal seams welding, Flange, fillet and flat welding

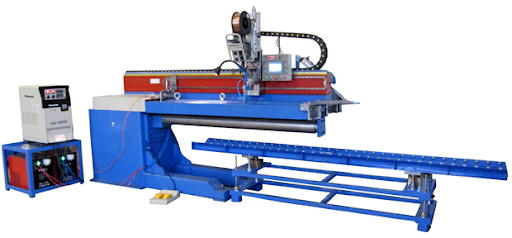

Weld-Fab Welding Head Manipulators

Weld-Fab Welding Head Manipulator Video

Why Choose Weld-Fab Manipulator?

√ Standard match with CSA & CUL and CE

√ Stable mechanical structure

√ Safety electrical design

√ Special customized loading capacity and dimension

√ Superior warranty and after service

FAQ about Welding Head Manipulator

Welding is an essential welding skill that welders are required to have. Welding head manipulators are complex welding tools that can be used for welding on the move, welding overhead, and welding in confined spaces. This will provide some answers to FAQs about this tool so you know what you’re getting into before you buy one.

Welding head manipulators are welding tools that allow the welder to work in areas that cannot be reached by welding from ground level. They can be used for welding overhead, welding on the move, or welding in confined spaces where it is difficult and dangerous to position a conventional weld torch. Here are some frequently asked questions about this tool.

What are welding manipulators?

The welding manipulator is an essential piece of equipment for any welder. The device allows operators to reach places that would otherwise be out-of-reach, giving them more flexibility in their work schedule and allowing greater productivity as well!

What welding head manipulators are available?

There are four main welding head manipulator types: ceiling-mounted, floor-based, vehicle mounted and gantry based. Ceiling mounted welding heads can be adjusted from the ground level but they need assistance to attach it on a working surface as it is heavy in weight. They also have limited welding range. Floor-based welding heads are the most popular type as they offer a good welding range and they can be easily attached/detached from the welder’s workstation. Vehicle mounted welding heads are ideal for welding in tight spots as it offers more welding range than ceiling-mounted welding heads but less than floor-based welding heads. Gantry welding heads are typically used in heavy-duty welding applications as they offer the widest welding range.

What are the benefits of using a welding head manipulator?

Welding head manipulators provide welders with increased welding range, which means they can weld in more difficult and dangerous positions. They also allow welders to work faster and more efficiently.

What is boom welding?

The welder is an industrial machine that has a “column” of metal going up and down, with the boom attached at one end. The other side contains welding equipment in order to create joints between two pieces or surfaces being joined together by this device – also known as hot-wiring!

What is manual welding positioner?

Using a welding positioner is one way you could be able to rotate or spin your workpiece. Manual, semi-automatic and automatic rotary welders are all available for purchase depending on what type of machine best suits the needs at hand!

If you have any other questions about welding head manipulator, please don’t hesitate to contact us. We would be happy to help you with anything related to welding head manipulator.

How Does a Welding Manipulator Work?

In case you’re starting to question if it involves a robotic arm 100% of the time, or if you need to manually move it, don’t fret – we got you.

Image of a worker toggling or working on a welding manipulator

Basically, a welding manipulator sets a welding head in motion in order to reach spots, heights, and places on the workpiece.

It can be a manual welding manipulator where you would have to position the device to its rightful area, and it can be automatic and pre-programmed.

You can think of how it works easily – think of a welding head that has an extended length. Thanks to this length, even if the project requires you to weld a 20-ft. vessel, you don’t have to risk climbing up to that height to weld what’s necessary.

That’s the general idea of how welding manipulators work

What Are the Parts of a Welding Manipulator?

Ideally, different versions and kinds of welding manipulators have different parts. However, there are “primary” parts that are common across all types and kinds of manipulators.

Image of a welding manipulator where the parts are highlighted

For instance, if you remove one of its primary components, the manipulator wouldn’t properly function.

Some of these primary parts include, but are not limited to:

- Welding bracket or support

- Control box (with motors)

- Welding gun support

- Welding head

- Pre-heat system

Without any of these, you wouldn’t be able to call a machine a welding manipulator.

What Are the Different Types of Welding Manipulators?

While the market is filled with a lot of welding manipulators, there are three (3) considered the most common and the most purchased due to the functionality and the usage that they hold.

Sample image of a column & boom weld manipulator

The most common types of welding manipulators include:

Column & Boom Welders

Column & boom welders are welding manipulators that you usually use for welding structural beams, as well as other kinds and types of structures that are big and large in size.

It’s called column & boom because it’s comprised of a column (vertical metal), and a boom (horizontal metal). The two (2) go and function together; the column is what you can thank for the locomotion flexibility that the boom can give you.

A column & boom weld manipulator is a machine you can use to automate welding in such a fashion that the welding head is the one moved and adjusted.

Rotary Welding Positioners

A rotary welding positioner is a type of a device or a machine that you can use to help you accurately position the workpiece.

Unlike column & boom, rotary welding positioners reposition and manipulate the workpiece, instead of the weld head.

Welding Rollers

Last but definitely not least are welding rollers.

They’re probably the least common type of welding manipulator in the market, but many business sectors and industries use this, too.

The idea behind weld rollers is for the welder to avoid slipping and inaccuracy when it comes to welding cylindrical objects and workpieces.

One good example is when a welder needs to weld a tank. It’s going to be hard to use a welding positioner for it, especially if it’s more than 50 kg – and that’s where the importance of welding rollers come in.

These are three (3) of the most common types of welding manipulators out in the market. Don’t be confused, there are others – these are only the favorites and the most used.

Can You Buy a Used Welding Manipulator?

Yes, there’s not a written rule saying that you should “never” buy a used manipulator.

As a matter of fact, buying a used welding manipulator holds too few benefits and advantages. For one, they’re going to be much cheaper and more affordable than a brand new one.

Another benefit of purchasing a used weld manipulator is that you already know that the product is working – you don’t need to test it out.

Upon purchasing, though, it will be in your responsibility to see if the manipulator is still in its good condition. It will be up to you to determine this.

Welding Manipulators vs. Welding Positioners

Many people ask – are welding manipulators and welding positioners the same?

Sample image of what a weld positioner looks like

Going back to the types of weld manipulators above, there’s one named “rotary welding positioners,” and it’s technically the same.

They are two (2) different machines, and while both of them carry the same goal – they don’t function in the same way.

In welding manipulators, we talked about how it moves and sets in motion the weld head. On the opposite end of the rope, a welding positioner is a type of auxiliary machine that moves and positions the workpiece.

Don’t be confused as to which is which; in fact, you can use both of them to complement each other!

What Specs Should You Look For in Welding Manipulators?

What do you look for in a welding manipulator? Are you sure that you’re choosing them based on how you need them? Or just based off of what others are looking for too?

When it comes to the specs or the specifications of weld manipulators, you need to make sure that you’re looking for the things that “you” or “your business needs.”

To help you with it further, here are some of the most important specifications.

Load Capacity

Load capacity refers to the maximum amount of load or stress that the manipulator is capable of withstanding without it underperforming.

Ideally, it’s the capacity of your manipulator to carry and to work on a particular material in terms of weight.

Column Stroke

The column stroke refers to the maximum distance or stroke in which the column is capable of moving.

Generally, the usual column stroke of welding manipulators lie around 55 to 65 inches.

Boom Stroke

Akin to the column stroke, the boom stroke is the distance that the boom is able to travel; and to give you the most general idea of the length of the boom stroke, it sits at about 39 to 50 inches.

Equipment Mass

This is the total weight of the welding manipulator.

NOTE: In checking the equipment mass, be sure to know if the attachments are included. Some manufacturers don’t include the attachments – this can result to improper weight adjustments for shipping, etc.

Power Requirement

The power requirement is what the machine needs in order for it to operate.

Unlike other specifications, the power requirement will depend on the type of motor used, as well as the functionality of the weld manipulator.

It will vary from one manufacturer to another.

Travel Car Speed

A travel car is a component or a part of a welding manipulator that can perform long seam welding.

Therefore, travel car speed is the rate in which the travel car can go from one point to another.

These are some of the most important specifications to note in purchasing a welding manipulator. To put emphasis on it – it’s not all of them. There are far more specifications – they’re just what a wide variety of clients and customers look for often.

Benefits You Can Get in Using Welding Manipulators?

We all know that automated welding is being seen as one of the most effective solutions to the worst welding problems we grew out of.

Highly efficient results of welding in using weld manipulators

Even if that’s the case, a lot of people still overlook the advantages of using weld manipulators.

In fact, here are some of the most notable benefits of using a welding manipulator:

Promotes a Safer Working Environment

The first thing to understand is that a welding manipulator promises a safer working environment.

With a welding manipulator, your welder wouldn’t be anymore required to be side-by-side with the 10-ton workpiece.

The welder can simply go back and forth to see if the program for a particular project is done right and accurately.

Gives You Faster Production Rate

What do we need machines for other than the fact that they can eliminate human intervention? – Speed.

With a welding manipulator, the amount and the volume of projects you can complete is truly unimaginable.

Several welders reported that they were able to finish a project at less than half the time when they were manually doing it.

Promises Precision and Accuracy in the Projects

Automated welding is not just existent to ensure that your projects will be done and accomplished fast – but also to make sure that the consistency and the quality of the weld is there.

Yes, human welders have the consciousness of a human, and therefore, can easily adjust. However, automatic welding manipulators or those that you can program are accurate and precise to what you have programmed them to do.

There’s going to be little room for errors, and that’s a guarantee.

Promotes More Mobility and Flexibility

And last but definitely not least is that it can give your welders mobility and flexibility.

Let’s say you have a welder that is not so tall – how would he be able to reach an 8-ft. weld? That’s easy if we consider using a welding manipulator.

No matter how high the weld needs to be, and no matter how stiff the welder is, a welding manipulator will be more than enough to do the trick.

Say goodbye to time-consuming welds that are too hassle and complicated. Finish the job earlier, faster, and with more accurate results!

Welding Processes You Can Use With Welding Manipulators

Would all types of welding be compatible in using a welding manipulator? Apparently, yes – but not all might be effective.

There are several welding procedures that might not find the success with weld manipulators. But, among those that have been proven and tested to work effectively include:

- MIG or Metal Inert Gas Welding (GMAW)

- TIG or Tungsten Inert Gas Welding (GTAW)

- Stick Welding

- Laser Welding

- Plasma Welding

- Submerged Arc Welding

What is a Pipe Welding Manipulator?

A pipe welding manipulator is a pretty self-explanatory machine.

Image of a pipe welding manipulator in action

It is a welding manipulator that you’d have to use if you are to work on pipes, tanks, vessels, and other rounded and cylindrical workpieces.

They’re specialized to have a good grasp of the workpiece even if it doesn’t have a rough edge.

Are There Portable Welding Manipulators in the Market?

Yes, you can purchase portable welding manipulators, and there are lots of them in the market.

Do note, though, that although they’re portable, they might not be able to give you the exact results you’re looking for.

As a matter of fact, you might not be able to use them for medium-to-heavy-duty applications.

What is a Seam Welder?

You can identify seam welding to be the welding of two (2) materials through electrical resistance heat generation.

Seam welding machine

The idea behind it, so you could understand it easier, is the word “seam.”

A seam welder, therefore, is a device or a machine that you can use to initiate the fusing or two (2) different materials down a never-ending seam.

Renting vs. Buying Welding Manipulators: Which One is For You?

The golden question that everyone wants to know the answer to. Would it be better to rent a welding manipulator or to purchase them outright?

This question is actually relative and the answer to this will vary depending on your business needs, your budget, and how you would use them.

Let’s take a look at the pros and cons of each.

Pros of Renting Welding Manipulators

Here are some of the benefits and advantages of renting out welding manipulators:

- Less stress about the maintenance of the machine

- You don’t need to shell out a huge amount of money to start

- Perfect for temporary and light-to-moderate use

- Wide variety of options in choosing which to rent

Cons of Renting Welding Manipulators

When it comes to the drawbacks and the cons of it, they are as follows:

- You don’t have total decision over the machine

- There are limits as to how you can use them

- You have to make sure it doesn’t wear off while you’re in a lease

- Extra charges may apply if the renting company deems that it wore out during your use

That’s what we have if you plan on renting welding manipulators. Now, let’s look at buying or purchasing them outright.

Pros of Buying Welding Manipulators

- You’ll have total control over the machine, how to use it, where to place it, etc.

- You will be able to study it thoroughly as you can dismantle and re-assemble it

- Your workers can perform a wider array of tasks with it compared to renting

Cons of Buying Welding Manipulators

Here are some of the disadvantages of purchasing welding manipulators vs. renting it out.

- It’s typically expensive – you’ll need a large sum of money for it

- The delivery could take about 7 to 12 days – even up to 3 weeks

- Might require a bit of experience for continuous automated welding

Those are the points that differentiate renting a welding manipulator from purchasing one.