Weld-Fab In Rotterdam, Netherlands

Weld-Fab In Rotterdam, Netherlands

Date: 29th, Oct 2019

Project located in Rotterdam, Netherlands

Project item: 50ton Fit-up Growing Line

Detailed description:

The Fit-Up Growing Line is mainly used for the assembly and welding of pipelines. Each section of the pipeline is assembled to the required length, and the operating machine is used to weld the circumferential seams. This combination is often suitable for the production of wind power equipment or the welding of foundation pipes.

At the beginning of September 2019, we received an inquiry from a customer in Rotterdam that the company produces foundation pipelines. They are preparing to start a new project. As a preliminary preparation for the project, they need to know the technical parameters of the Fit-Up Growing Line and the benefits it can bring in order to make reasonable arrangements for the project. Our engineers actively cooperate to answer all the questions of our customers, which greatly improves our customers’ trust in us and their professional recognition.

At the beginning of October, in the joy of welcoming the National Day, we also received the customer’s first PO, 2 sets of 50 ton Fit-up Growing Line. In order to ensure that the customer’s project can proceed smoothly as scheduled, we delivered the two sets of equipment in just 25 days. After the equipment arrived at the customer’s factory, we arranged two engineers to go to the customer’s factory to install and debug the equipment. With the cooperation of the production manager, we completed all the work within two days.

Since it is the first purchase for a new customer, we provide customers with a 13-month warranty and lifetime technical support. Today, our equipment is still running very well.

This is a very good beginning. With the first pleasant cooperation as the foundation, we believe that in the future, when customers have needs, they will still choose Weld-Fab.

Weld-Fab In Gemlik,Turkey

Weld-Fab In Gemlik,Turkey

Date: 15th, March 2015

Project located in Gemlik,Turkey

Project item: 80 ton self-aligning welding rotator/ 150 ton self-aligning welding rotator

Detailed description:

The client company is the largest foundation pipe manufacturer in Turkey. Customer have higher requirements for welding equipments. The pipe diameters they produce can reach up to 4000mm to 5000mm. Therefore, we adopted dual drive to ensure that the torque output can meet the requirements, so that the speed and smoothness of operation can be guaranteed. In addition, polyurethane wheels are used to increase the friction between the rollers and the pipe cylinder, so that the cylinder can run smoothly. The particularity of the polyurethane material results in the rollers being wear-resistant and high-temperature resistant.

After discussing the technical requirements, the customer readily placed the first order and purchased 10 sets of 80-ton self-aligning welding rotator and 5 sets of 150-ton self-aligning welding rotator.

The equipment was delivered in 40 days. After the Chinese New Year holiday, our two engineers flew to Turkey and then went to Gemlik. Turkey is located at an important geographical location at the junction of Europe and Asia. Most of it belongs to plateau topography, the crust continues to change, and earthquakes are frequent. Gemlik Port is one of Turkey’s large industrial container ports. Our engineers completed the commissioning of all the equipment within three days after arriving in Gemlik, and visited their factory on the last day, they had a good talk about the foundation pipe and welding technology. Thank you very much for the warm hospitality of the company’s leaders.

After that order, we still maintain a good cooperative relationship and often discuss technical issues.

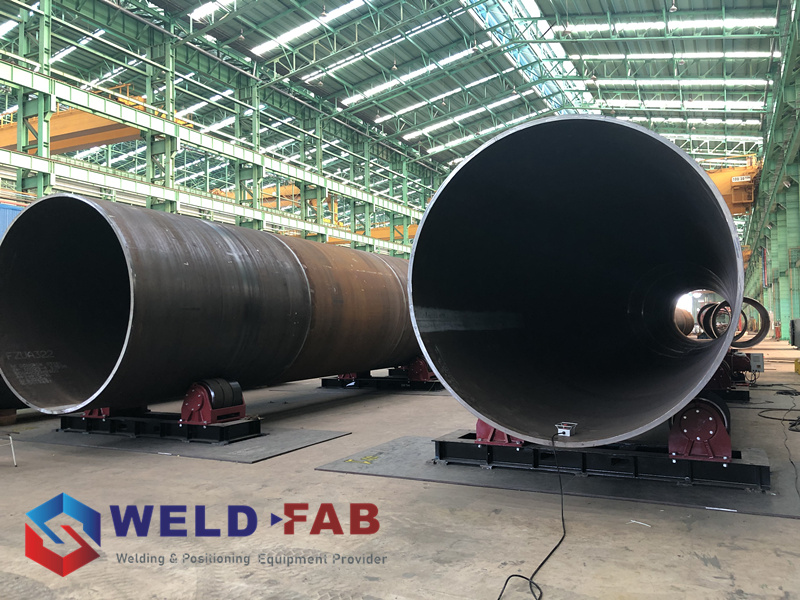

Weld-Fab In Vung Tau,Vietnam

Weld-Fab In Vung Tau,Vietnam

Date: 8th, May 2017

Project located in Vung Tau,Vietnam

Project item: 100 ton conventional welding rotator/ 200 ton conventional welding rotator/ 300 ton conventional welding rotator/ 800 ton conventional welding rotator/1000 ton conventional welding rotator

Detailed description:

After many years of operation, Weld-Fab has always focused on customer needs, doing its best to solve customer problems encountered in production, and provide customers with the most suitable equipment. Therefore, many users have been accumulated in Vietnam. These users exist in various industries, producing pressure vessels, foundation pipelines, wind tower projects, etc. It is with these customers for many years of experience in cooperation, making Weld-Fab has studied the related fields of wind power generation equipment.

This customer produces foundation pipes. Their pipe diameter and weight are very large, so all they need are large welding rotators. After understanding the customer’s project requirements, we provided the customer with a detailed proposal as a reference. conventional welding rotators of 100 ton/200 ton/300 ton are used for the production of wind tower, and 800 ton/1000 ton are used for the production of monopile. The customer also ordered a welding manipulator to be used for welding the longitudinal and circumferential seams of the pipeline. The welding machine of the welding manipulator uses the Lincoln Tandems Welding System.

After the engineers arrived in Vietnam to complete the commissioning, they visited our other customers in Vietnam by the way to check about the use of the equipments and discuss the development of the future projects. Weld-Fab will provide customers with a warranty. If any accessories are damaged during the warranty period, we will mail replacement accessories immediately.

With many years of experience, Weld-Fab has been recognized by many customers. We also provide technical services for other wind tower manufacturers in the United States, Canada and other regions.

Weld-Fab is constantly improving and becoming more professional, which allows customers to think of us first and trust our products and services when they are launching new projects.

Weld-Fab In Rayong,Thailand

Weld-Fab In Rayong,Thailand

Date: 20th, April 2018

Project located in Vung Tau,Vietnam

Project item: 5 ton conventional welding rotator/ 10 ton conventional welding rotator/ 20 ton conventional welding rotator/ 60 ton conventional welding rotator/100 ton conventional welding rotator/ 200 ton conventional welding rotator

Detailed description:

Speaking of Thailand, people’s first impression of it must be the Island, Buddhist culture and Wonderful nightlife. But in fact, Thailand also has three pillar industries, manufacturing agriculture and tourism. Thailand’s manufacturing industry involves mining, petroleum, chemical industries, etc., so there are many factories that produce pressure vessels and heat exchangers.

This Thai customer mainly produces pressure vessels. The customer showed us the main production parts of their factory, so that we can better understand their products and design welding equipment that is more suitable for their products. Due to the different sizes of the customer’s workpieces, in order to be able to weld different sizes of cylinders at the same time, the customer purchased several types of self-aligning welding rotator, such as 5 tons / 10 tons / 20 tons / 60 tons / 100 tons / 200 tons, etc,.

The self-aligning welding rotator only needs to place the workpiece within the effective range of the roller, and can automatically adjust the center distance of the wheel, reducing manual operation and very simple to use. In order to realize automatic welding, the customer also ordered the welding manipulator to be used with the welding rotator. This combination can effectively improve the production efficiency. For this welding manipulator, we have configured a Lincoln DC100 welding machine for our customers. Weld-Fab also provides many other optional configurations for installation on the operating machine. As long as customers have needs, Weld-Fab will do its best to solve them.

Weld-Fab In Dallas, TX

Weld-Fab In Dallas, TX

Date: 10th, August 2019

Project located in Dallas, TX

Project item: 20/40/60/150/200 ton conventional welding rotator with motorized moving, 5 ton welding positioner, LH4040 welding manipulator

Detailed description:

This customer is from Dallas, USA. Is a large-scale production line manufacturer, mainly produces renewable energy and pressure vessel related equipment. Since the manufacturer does the production line, in order to improve efficiency, it is necessary to purchase a lot of equipment to support production.

Our general manager visited the factory during a business trip in 2018, and the large-scale production line was shocking. During the conversation, the company’s production manager was very interested in our products, and the operation of the welding rotator can bring full convenience to the production. In the summer of the following year, we received purchase requests from customer.

All for convenience and improving production efficiency. We have produced 20/40/60 tons of welding rotators with motorized moving for customer. This type of welding rotator can automatically transport the cylinder body so that the two cylinder bodies are aligned with each other, and then work with the operating machine to weld the circumferential seam. The motorized moving welding rotator can reduce manual walking and transportation, which is fast, convenient and easy to operate. According to customer needs, we have also customized the LH4040 model welding manipulator, the horizontal arm can move up to 4000mm horizontally, and the column can be raised and lowered up to 4000mm vertically. The welding rotator is matched with the welding manipulator to realize automatic welding, which is very practical.

Due to production needs, the customer ordered 5-ton positioners to assist welding. The cylinder is placed on the table of the positioner, and the positioner can be controlled to flip and rotate at a uniform speed to facilitate welding from all angles. The table of the positioner can also be matched with a chuck to fix the cylinder.

Due to the large volume of customer orders, our factory delivered all the equipment to the customer after 50 days of production. And one month later, two engineers were arranged to go to Dallas to help customers install and debug. After a week of hard work, under the active coordination of the production department, our engineers completed the commissioning of all equipments. During this week, the client did their best as a landlord, received our engineers very warmly, and had many technical discussions and exchanges, which laid the foundation for future cooperation.

In the following days, in order to expand production, the manufacturer successively ordered 150-ton and 200-ton motorized moving welding rotator from Weld-Fab. This is enough to show that Weld-Fab’s products are very reliable, and our professionalism has won the trust of customers. Weld-Fab will continue to improve its professionalism, and our products must satisfy every customer.

Weld-Fab In Brisbane,Australia

Weld-Fab In Brisbane,Australia

Date: 22th, April 2019

Project located in Brisbane,Australia

Project item: 20/40 ton fit-up pipe growing line, LH5090 welding manipulator, CNC plasma cutting machine

Detailed description:

Australia is also one of our main markets. Weld-Fab cooperates with many Australian pipeline production companies. This customer is a steel manufacturing company that specializes in steel-related products, such as pipes, wind towers, etc.

Our customer received an infrastructure project in Australia in early 2019, and the project needs to provide large quantities of foundation pipelines. At the early stage of project preparation, the customer contacted us and informed us of the project requirements. We have formulated a 20/40 ton Fit-Up Pipe Growing Line program according to customer requirements. As the time reserved for this project is very tight, mass pipeline production needs to be delivered within the specified time. The customer requires that all welding rotators need to work uninterrupted for 24 hours, so there is a very high requirement for the equipment to be able to work continuously and stably

With years of expertise in equipment, Weld-Fab has equipped customers with reducers, motors and electronic controls that can load a large amount of work. At the same time, we promise to provide customers with a 24-month warranty, and any spare parts will be replaced in time. This series of work is only to ensure timely delivery of customers and complete this project perfectly.

Of course, such a huge project is not enough to be completed by only relying on the equipment of the Fit-Up Pipe Growing Line. The Fit-Up Pipe Growing Line is mainly used for assembling pipelines, which is convenient for welding. To achieve high-efficiency completion of automatic welding work, it also needs to be used with the welding manipulator. When communicating the plan, the customer also put forward the demand for the welding manipulator. We have customized the LH5090 model welidng manipulator for the customer according to the customer’s workpiece. Because the customer still needs a lot of work to cut steel plates, they also ordered a CNC plasma cutting machine. The CNC plasma cutting machine is also a fully automatic cutting equipment, only the operator needs to set the cutting program, the equipment will automatically cut the steel plate according to the demand, which greatly reduces the manpower and improves the work efficiency.

Due to the tight schedule of the customer’s project, all Weld-Fab employees worked 100% hard, worked overtime, and completed the production and delivery of all equipment within 35 days. After the equipment arrived at the customer’s factory, we immediately dispatched our engineers to Brisbane to debug the equipment. Weld-Fab’s engineers have already commissioned equipment in many factories in Australia. The enthusiasm of the Australian people makes us feel at home every time.

Now, the customer’s infrastructure project has been completed, and Weld-Fab’s equipment is still running smoothly. Looking forward to the customer’s next project to meet us again.

Weld-Fab In Batam,Indonesia

Weld-Fab In Batam,Indonesia

Date: 8th, June 2019

Project located in Brisbane,Australia

Project item: 100 ton self-aligning welding rotator

Detailed description:

Batam Island in Indonesia opened a free port in 1978 and plans to develop into a diversified industrial and commercial center and tourist destination. In the 1980s, they started to build infrastructure. This has led to a great development in Batam’s manufacturing industry. This customer is a manufacturer in Batam, which mainly produces pressure vessels and heat exchangers.

The production of pressure vessels and heat exchangers requires a lot of welding work. In order to reduce tedious steps and improve productivity, the customer intends to purchase a batch of self-aligning welding rotators. The customer’s request is relatively simple, which can bear a cylinder of 80-90 tons, and easy to operate and easy to use. Weld-Fab quickly provided a solution based on customer needs, the HGZ-100 model self-aligning welding rotators. This set of welding rotator can bear a weight of up to 100 tons, and can automatically adjust the center distance, which is very convenient to use. The double-drive reducer can well control the smoothness of equipment operation. After two weeks of technical discussion and consideration, the customer finally chose Weld-Fab and sent the first PO.

Our production department delivered all the equipment ordered by the customer in just 25 days. Since the customer has previous experience in using this type of equipment, the steps of our engineers to go to the site for debugging are omitted. If you have any questions, you can contact Weld-Fab directly, and our professionals can quickly give answers and solutions.