The Welding Positioner Used In Bucket

Bucket is a kind of grabbing workpiece installed on excavator, also called bucket.

According to the working mode, it is divided into backhoe bucket and front shovel bucket. Generally, backhoe bucket is commonly used.Bucket is a bucket-shaped member used to excavate loose materials such as soil, yellow sand, stones and construction waste. It is composed of bottom plate, wall plate, hanging ear plate, ear plate, tooth plate, side plate, bucket teeth, side teeth and other parts.

Bucket is a kind of work device that is often installed on excavators for excavation. Therefore, welding is the most critical manufacturing process of the bucket. The quality of welding directly affects the structural strength and service life of the bucket.

Buckets can be divided into three categories according to their production materials:

Standard bucket: Use domestic high-quality alloy steel, suitable for general clay, loose soil excavation, and sand, soil, gravel loading and other lighter operating environments. Equipped with standard plate thickness and high-quality bucket tooth seat.

Reinforced bucket: The vulnerable parts of the reinforced bucket are made of domestic high-quality high-strength wear-resistant steel, suitable for heavy-duty operations such as digging hard soil mixed with softer gravel or loading of gravel and gravel. The selected plate is thicker, and the use of high-quality bucket tooth seat can prolong the service life.

Rock bucket: The tooth seat plate and the side blade plate are made of ultra-high-strength wear-resistant steel imported from Sweden, which is suitable for digging hard soil, sub-hard stone, weathered stone or hard stone mixed with harder gravel, and a reinforcement plate is added at the bottom. Add side guards and install guards. The bucket tooth seat is made of special rock type products, so it has strong wear resistance and bending resistance.

Buckets are equipment accessories for special industries. Special equipment is needed to efficiently and high-quality production and processing operations, such as: CNC plasma cutting machine, bevel milling machine, plate bending machine, welding positioner, boring machine, etc.

The manufacturing process of the bucket includes cutting, turning, milling, drilling, forming, welding, polishing, sandblasting, spraying and other processes.

In the working process, the bucket is a powerful grasping accessory, which is mostly used for some large-scale lifting equipment, so there are strict standards for its welding process.

- The influence of the welding process directly determines the tensile strength and bending performance of the welded joint. The main influencing factors are the choice of base material, the brand of welding rod, the type of shielding gas, and the most important welding method. The above four factors must be re-evaluated and evaluated at which link the above four factors appear to be flawed.

- In the bucket manufacturing, if two or more welding methods are used in the same weld, the welding process must be qualified. Don’t think that these minor details are not important. These will also directly affect the service life and failure rate of the subsequent bucket.

- On the production line, the welding of the bucket has strict implementation standards. The production technician must strictly supervise and guide correctly to avoid detours, which affects the normal use of the equipment and maximizes the efficiency of the bucket. .

Since welding is very important for bucket processing, the equipment used to assist welding is also extremely important.

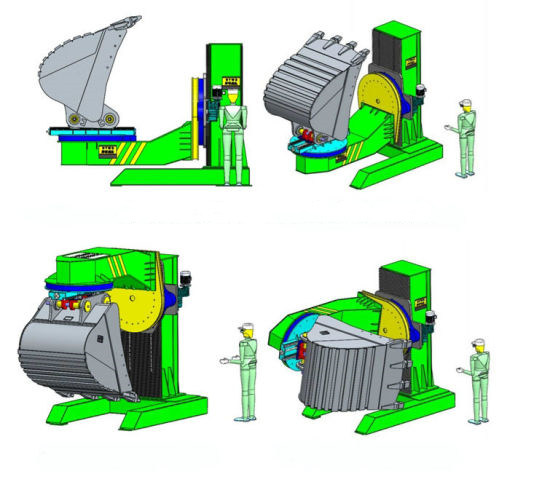

Buckets are large equipment accessories, in addition to irregular body shape, the weight is also very large.During the welding process, it is difficult to move the bucket manually. It is very difficult to change the welding angle by the welder’s own movement.And it takes time and manpower. In this case, it can be easily solved with the help of a welding positioner or a welding turning table.

The welding positioner can drive the bucket to turn the angle within a certain range, or rotate at a constant speed, allowing the welder to perform welding work at any height.

According to the weight of the bucket, the corresponding positioner is selected, without manual movement, which can reduce manual labor.

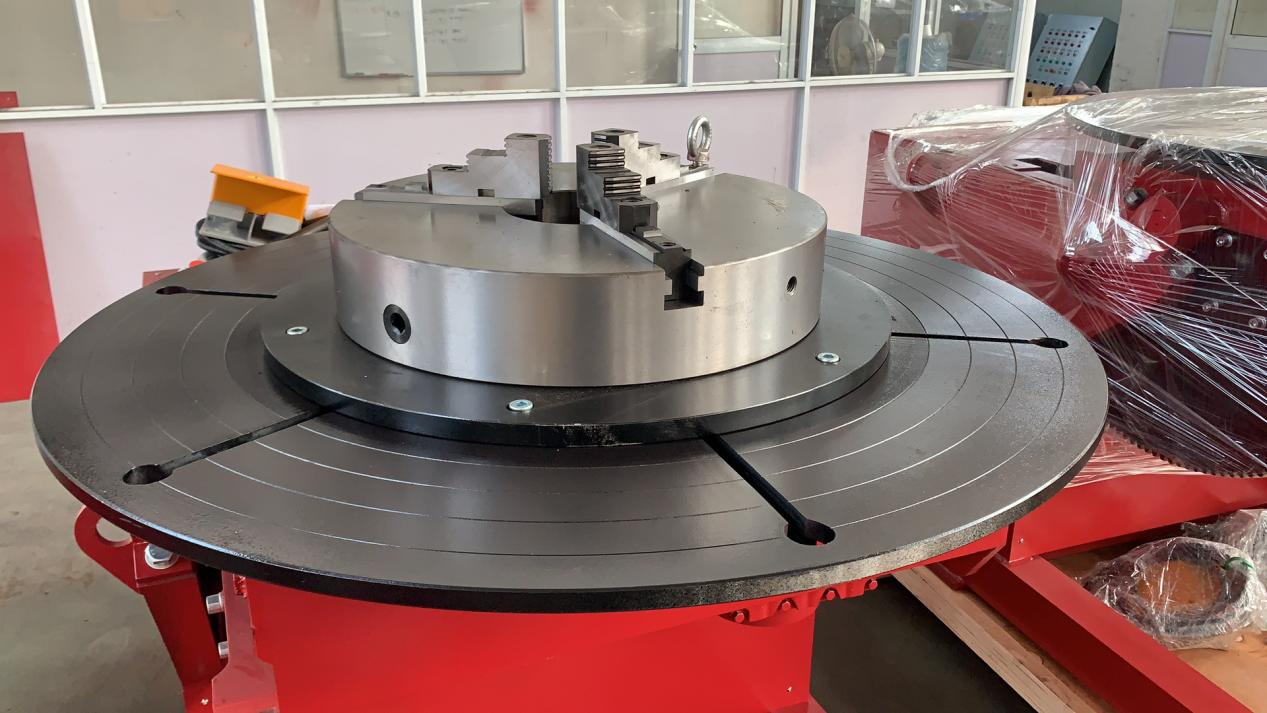

The welding turning table can play the role of support and rotation. If you don’t need to turn the bucket to a specific angle, you can choose the turntable to assist welding.

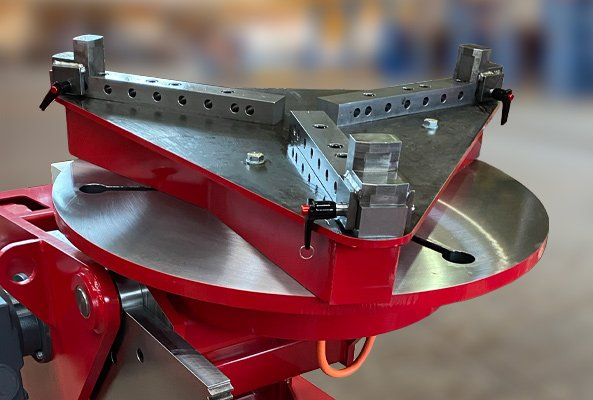

However, the irregular nature of the bucket makes it difficult to fix it on the welding equipment. Therefore, we can fix it with the help of a chuck.

The chuck is a mechanical device used to clamp the workpiece on the machine tool. A machine tool accessory for clamping and positioning the workpiece by using the radial movement of the movable jaws evenly distributed on the chuck body.

The chuck is generally composed of a chuck body, a movable jaw and a jaw drive mechanism. The chuck body has a minimum diameter of 65 mm and a maximum of 1500 mm. There is a through hole in the center for the passage of workpieces or bars.

From the number of chuck jaws, it can be divided into: two-jaw chuck, three-jaw chuck, four-jaw chuck, six-jaw chuck and special chuck. From the use of power, it can be divided into: manual chuck, pneumatic chuck, hydraulic chuck, electric chuck and mechanical chuck. From the structure can be divided into: hollow chuck and real chuck.

The back of the chuck has a cylindrical or short tapered structure, which is directly connected to the end of the machine tool spindle or through a flange. Both the welding positioner and the welding turning table can reserve T-slots to install the chuck according to the specific conditions of the workpiece.

If you don’t know how to choose a welding positioner or welding turnign table that suits you, Weld-Fab has a professional design team and sales team that can recommend the best matching equipment for you.