The Welding Manipulator Used In Tank And Vessel

The welding manipulator is a kind of mechanical equipment that can move the welding head to the required position for welding, so as to facilitate manual welding, semi-automatic or automatic welding. To ensure the stability of the welding process.

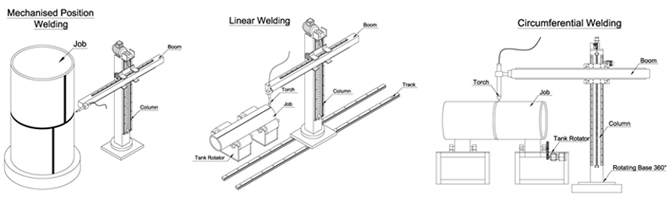

Common welding manipulators include platform type, elbow arm type, gantry type, etc. The welding manipulator is often used with the welding rotator to complete the welding of circular container circular seams and longitudinal seams.

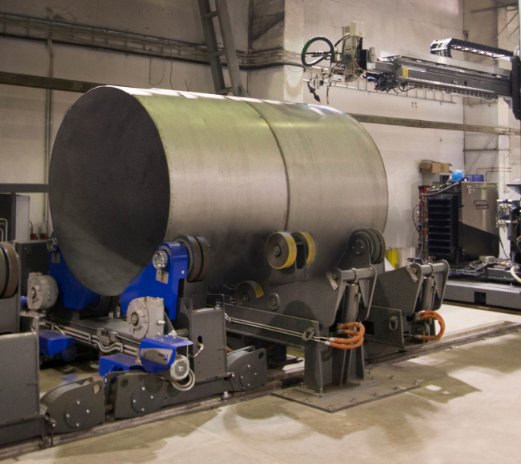

In the production of many large industrial equipment, manipulators are used to assist production. The most used are Tank and Vessel.

The sealed container used to store liquid or gas is the tank. Steel tank engineering is an essential and important infrastructure for industries such as petroleum, chemical, grain and oil, food, fire fighting, transportation, metallurgy, and national defense. Our economic life is always inseparable from large and small steel tanks.

Metal oil tank is a container welded from steel plate material. According to the different materials and specifications of the container, the main body is made of stainless steel, carbon steel, and low-alloy steel.

The most commonly used steel structure vertical cylindrical oil tank is taken as an example. The oil tank mainly consists of an oil tank foundation, a bottom plate, a wall plate, a top plate and an oil tank accessory.

Oil tanks are also widely used. Because it has the ability to withstand higher positive pressure and negative pressure, it is beneficial to reduce the evaporation loss of oil and also reduces the risk of fire.

It is suitable for small distribution oil depots, rural oil depots, urban gas stations, military field oil depots or enterprise-affiliated oil depots. It is also used as auxiliary oil tanks in large oil depots, such as emptying tanks and metering tanks.

Horizontal oil tank is a long container used to store crude oil, vegetable oil, chemical solvent, water or other petroleum products. Horizontal oil tanks are composed of end caps, horizontal circular or oval tank walls and saddles, and are usually used in production links or gas stations. The volume of a horizontal oil tank is generally less than 100 cubic meters. It is generally round, oval, and other irregular shapes.

Gas tank refers to a container specially used to store gas, and at the same time it plays a role in stabilizing the pressure of the system.

According to the pressure of the container, it can be divided into high pressure vessel, low pressure vessel, and normal pressure vessel.

According to the material of the container, it can be divided into: carbon steel vessel, low alloy steel vessel, and stainless steel vessel.

The vessel is generally composed of parts and components such as a cylinder, a head, a flange, a connection pipe, a sealing element, and a support. In addition, it is also equipped with safety devices, meters and internal parts for different production processes.

A vessel structure used to store gas in urban gas supply projects. The role of the vessel is to store gas or liquid. It is also used in petroleum, chemical and metallurgical industries.

According to different storage pressures, it is divided into low pressure and high pressure. The former is divided into wet and dry according to the structure.

The welding manufacturing process of the container can generally be divided into: Raw material acceptance, marking, cutting, rust removal, machining (including edge planing, etc.), rolling, assembly, welding (product welding test plate), non-destructive testing, hole marking, general inspection, heat treatment, pressure test, anti-corrosion etc.

Among them, different welding methods have different welding processes. The welding process is mainly determined according to the material, chemical composition, structure type of the weldment, and welding performance requirements of the welded workpiece. We must first determine the welding method. There are many types of welding methods, which can only be selected according to the specific situation.

The welding head of the welding manipulator can be selected according to the welding method required by the workpiece, usually submerged arc welding, gas shielded welding or argon arc welding can be selected.

After the welding method is determined, the welding process parameters are formulated. The types of welding process parameters are different.

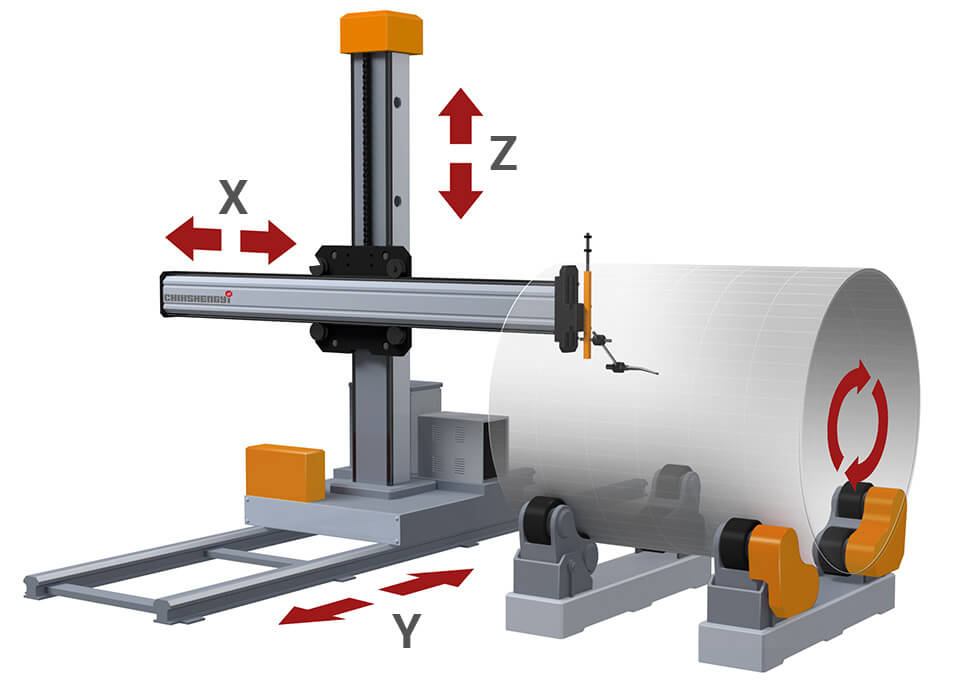

The welding manipulator is generally composed of columns, booms, slewing mechanisms, trolleys and other components. Each component is a building block structure. Generally, columns and booms are the basic components, and the remaining components can be selected according to customer requirements.

The columns and booms adopt bending and welding structural parts, which have very good rigidity. The light, medium, and heavy welding manipulators all use triangular guide rails, and the super heavy use flat square guide rails, all of which are processed by a planer.

Ensure the high precision and wear resistance of the guide rail. It is applied to the longitudinal seam welding and girth seam welding of the inner and outer seams of cylindrical workpieces such as vessels and tanks.

Since the welding manipulator can weld various welds of metal containers, metal welding structural parts, etc., it is widely used in many industries such as wind power equipment, pressure vessels, petrochemicals, pipelines, steel structures, boilers, shipbuilding, and surfacing repair.

The welding manipulator can also be equipped with electric carriages, inner telescopic arms, manned devices and maintenance ladders according to user requirements, and can also be equipped with various tracking and monitoring, arc swing, flux recovery and conveying devices, etc.

The control system of the welding manipulator adopts digital control mode, which is convenient to operate and precise in control, and it is also very convenient to control the linkage with other equipment.