The Welding Manipulator Used In Pipe

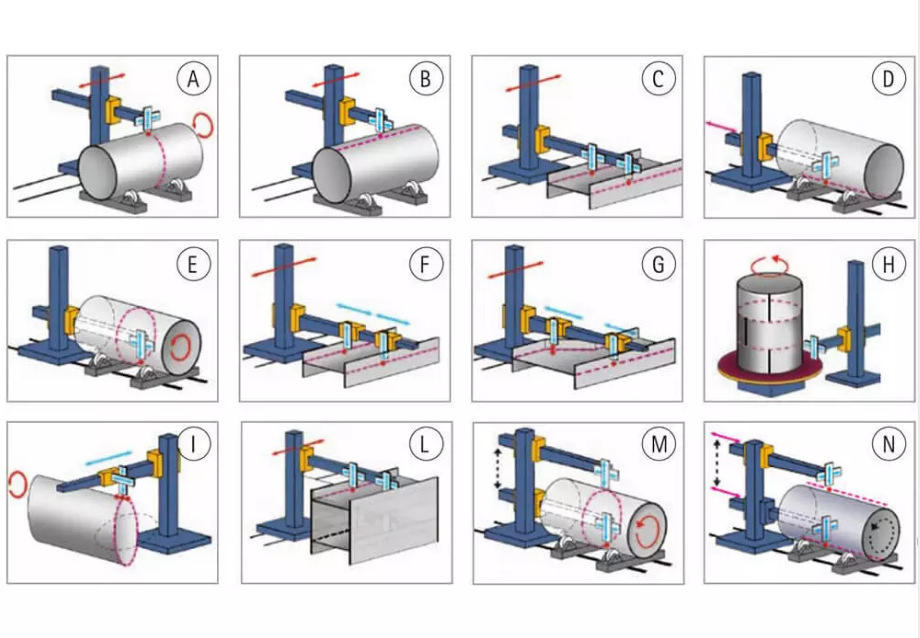

The welding manipulator is a special equipment for automatic welding of the inner and outer circumferential seams, fillet welds, and inner and outer longitudinal seams of the components in combination with the welding rotator and the welding positioner. It has a variety of structural forms such as fixed, rotary, and all-position.

The welding manipulator can select the structure according to the user’s needs and support various welding machines, and add auxiliary functions such as tracking, swing, monitoring, and flux recovery and transportation.

The welding manipulator designed by Weld-Fab has a unique cross-beam and column cross-section design, with post-weld stress relief treatment, and shape after planing and grinding.

The frame has light weight, high strength and good stability. The design of the telescopic arm inside the beam can effectively increase the horizontal telescopic distance of the boom.

The lifting and lowering of the boom of the welding manipulator adopts the AC motor constant speed method, and the lifting is stable and uniform during operation. Therefore, the safety factor is high, and there is a safety anti-falling device.

The expansion and contraction of the boom, the electric rotation of the column and the electric trolley all adopt AC motor frequency conversion stepless speed regulation. Constant torque output, stable speed (especially at low speed).

The response to start or stop is quick, and the response can be given immediately once the operation is performed. The machine has a speed digital display and can be preset.

The rotation of the welding manipulator’s column is divided into manual and electric. The slewing support adopts products of well-known brands in the industry, comes with high-precision gears, rotates flexibly, and can be manually locked to improve safety.

The trolley of the welding manipulator adopts the standard railway track as the walking track, which is divided into two types: manual and electric. Manual is suitable for light-duty and small-moving manipulators, while electric is suitable for heavy-duty or large-moving manipulators.

The operation of the welding manipulator adopts a manual control box and a head control box (welding control box) to form a near control and a remote control mode. The operation is flexible and convenient. Weld-Fab can also reserve a linkage interface in the electrical box, which can realize synchronous linkage with the roller frame, positioner, circular rotary table, etc.

In the production of large-scale industrial equipment, manipulators are often used to weld the longitudinal and circumferential seams of circular cylinders, such as pipes.

Pipelines refer to devices that are connected by pipes, pipe couplings and valves to transport gases, liquids or fluids with solid particles.

Generally, the fluid is pressurized by blowers, compressors, pumps, boilers, etc., and then flows from the high pressure of the pipeline to the low pressure. It can also be transported by the fluid’s own pressure or gravity.

Pipes have a wide range of uses, mainly used in water supply, drainage, heating, gas supply, long-distance transportation of oil and natural gas, agricultural irrigation, hydraulic engineering and various industrial installations.

The foundation of the pipeline is divided into three parts: foundation, base and pipe seat.

Most of the main pipelines for water supply, drainage, heating, and gas supply in cities and long-distance oil and gas pipelines are laid underground, while the process pipelines in factories are mostly laid on the ground for easy operation and maintenance.

Pipeline passage, support, slope and drainage, compensation, heat preservation and heating, anti-corrosion and cleaning, identification and painting and safety, etc., are important issues for both above-ground and underground laying.

In addition, pipelines can also be used to transport subsea natural gas, oil and other media.

The pipeline that transports petroleum crude oil or petroleum products is a pipeline that transports petroleum crude oil or petroleum products from oil fields to factories, transfer stations, and ports.

Steel pipes are generally used, and oil-resistant rubber pipes or specially treated plastic pipes are sometimes used for short-distance transportation. It is covered with insulation and protective layer, because the oil pipeline can only transport liquid petroleum products, not solid petroleum products, and is usually buried in the ground (in most cases).

These industrial pipes are usually large in diameter, and it is difficult to reach this height manually when the welded seam is exited, and it is also inconvenient to weld. Therefore, it is necessary to use a welding positioner to complete the operation.

The welding manipulator is generally composed of columns, beams, slewing mechanisms, trolleys and other components.

When it is running, the welding head or welding gun can be sent and kept at the position to be welded, or the flux can be moved along the specified track at the selected welding speed, which is very convenient for welding operations.

The welding manipulator has functions such as welding speed adjustment, welding operation and welding adjustment.

The welding operation is set on the control box and is mainly used to adjust the position of the equipment. The control system has a linkage interface, which is used to clamp the auxiliary forging machine that cooperates with the hydraulic press or the forging hammer to complete the main actions such as feeding, turning, and turning.

The welding manipulator can also be matched with a special welding piece displacement machine. The cylinder body can be clamped at one time, and the left and right sides can be welded with two welding torches at the same time, which greatly improves the processing accuracy and production efficiency.